Introduction: a scenario most construction leaders recognise

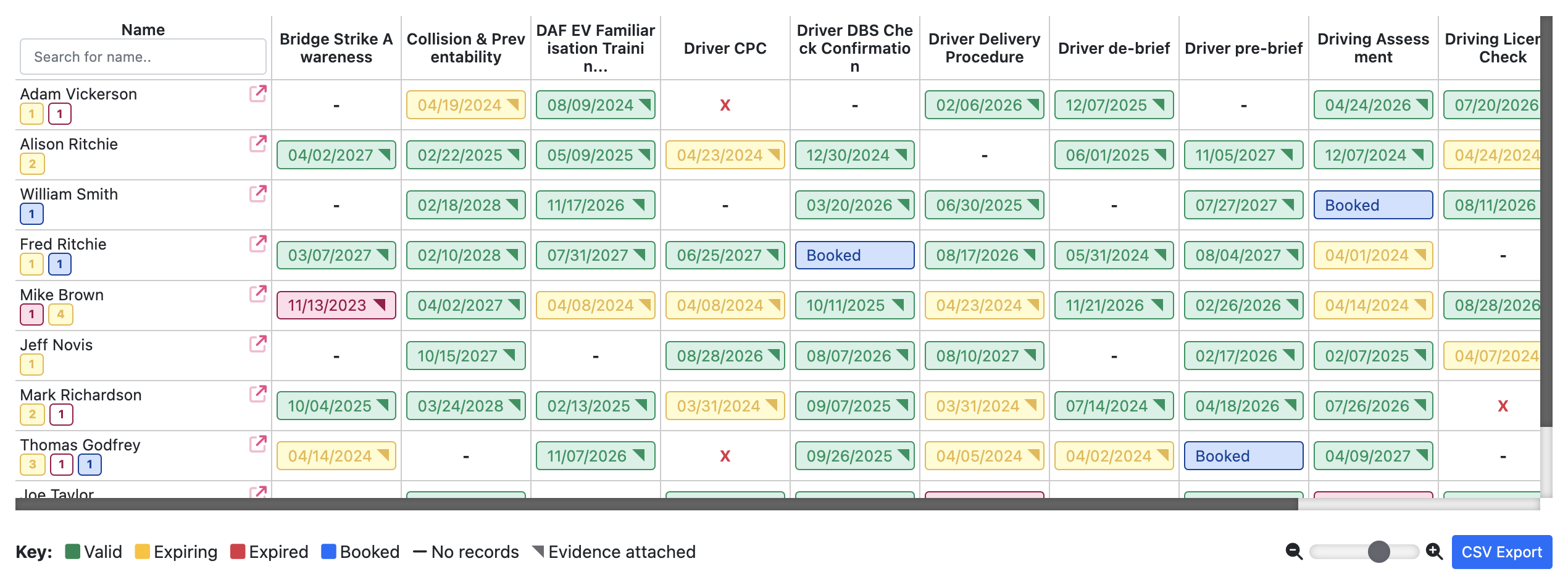

A site team fully mobilises the project. Supervisors approve RAMS, complete inductions and file training records. Supervisors assume competence because everyone “has the tickets”. However, midway through the project, a near miss occurs involving plant operation outside a worker’s usual scope. When the principal contractor later requests evidence of competence, typically held within a construction skills matrix, the team uncovers fragmented records. Certifications have expired. Managers never update role changes as responsibilities shift on-site. As a result, what appeared compliant on paper fails under scrutiny.

This scenario is not exceptional. Instead, it reflects a structural weakness in how the construction industry manages training, competence and safety assurance. Incidents rarely occur because organisations fail to provide training altogether. They occur because organisations lose visibility of competence as projects, roles and risk profiles change.

TABLE OF CONTENTS-

- Introduction: a scenario most construction leaders recognise

- The reality of construction risk and workforce complexity

- What recent research reveals about training, competence and incidents

- Why training records alone are no longer sufficient

- The role of a skills matrix in construction safety management

- Why spreadsheets break down at scale

- A platform built for live competence control in construction

- What effective competence management delivers in practice

- Conclusion: making competence visible, current and defensible

- FAQs

- References

The reality of construction risk and workforce complexity

Construction operates in constant change. Projects run for limited periods, sites change daily, and organisations assemble teams from direct employees, subcontractors and temporary labour. Teams manage safety through layered controls such as RAMS, permits to work, supervision and task-specific training. However, every one of these controls relies on a single assumption: that workers remain capable at the moment they carry out the task.

When this assumption fails, the consequences are severe. In Great Britain, construction continues to record the highest number of workplace fatalities of any sector. For example, in 2023/24, 124 workers died from workplace injuries, with construction accounting for the largest share (HSE, 2024). Non-fatal injuries and work-related ill health remain widespread, particularly musculoskeletal disorders linked to manual handling and repetitive tasks (HSE, 2024).

Despite this, many organisations still rely on fragmented training records that cannot keep pace with operational change. As operatives move between sites, take on different responsibilities or work under new supervisors, competence assumptions persist long after the evidence has expired.

What recent research reveals about training, competence and incidents

Research shows that safety competencies, which integrate knowledge, skills and behaviours, are foundational to a sustainable safety climate and influence safety performance beyond the effects of traditional training delivery (Rahman, 2022).

In the United States, construction accounts for approximately one in five occupational fatalities, despite representing a far smaller proportion of the workforce (OSHA, 2023). Falls, struck-by incidents and equipment misuse remain the leading causes of death, with OSHA guidance consistently highlighting the role of inadequate training, supervision and hazard recognition in these outcomes (OSHA, 2023).

Safety culture research supports this view. While leadership commitment and communication are important, safety culture is sustained through demonstrable occupational competencies. Without structured competence systems and reliable visibility of workforce capability, organisations risk assuming safety rather than evidencing it (Abikenova et al., 2023).

Regulatory guidance reflects this shift. Both HSE and OSHA emphasise that employers must ensure workers are competent for the work they undertake and that training is refreshed and appropriate to changing risk, not simply completed once (HSE, 2024; OSHA, 2023).

Why training records alone are no longer sufficient

Traditional training records answer a limited question: Has this person attended a course?

They do not answer the questions that matter most in construction:

- Is this person competent for this task, on this site, today?

- Does their competence align with the RAMS and permit requirements?

- Has their role changed since their last assessment?

As projects become more complex, these gaps become more dangerous. Training records stored in spreadsheets or disconnected systems quickly become outdated and inaccurate. Certifications expire unnoticed, temporary role changes are not captured, and subcontractor records are inconsistent. During audits or investigations, organisations struggle to demonstrate who was competent at a specific point in time.

👉 Suggested reading: Spreadsheets vs Training Matrix: Why Manual Tracking Fails at Scale. This explains why spreadsheets struggle to keep training and competence records accurate as organisations grow, and therefore, how fragmented tracking increases compliance and safety risk.

The role of a skills matrix in construction safety management

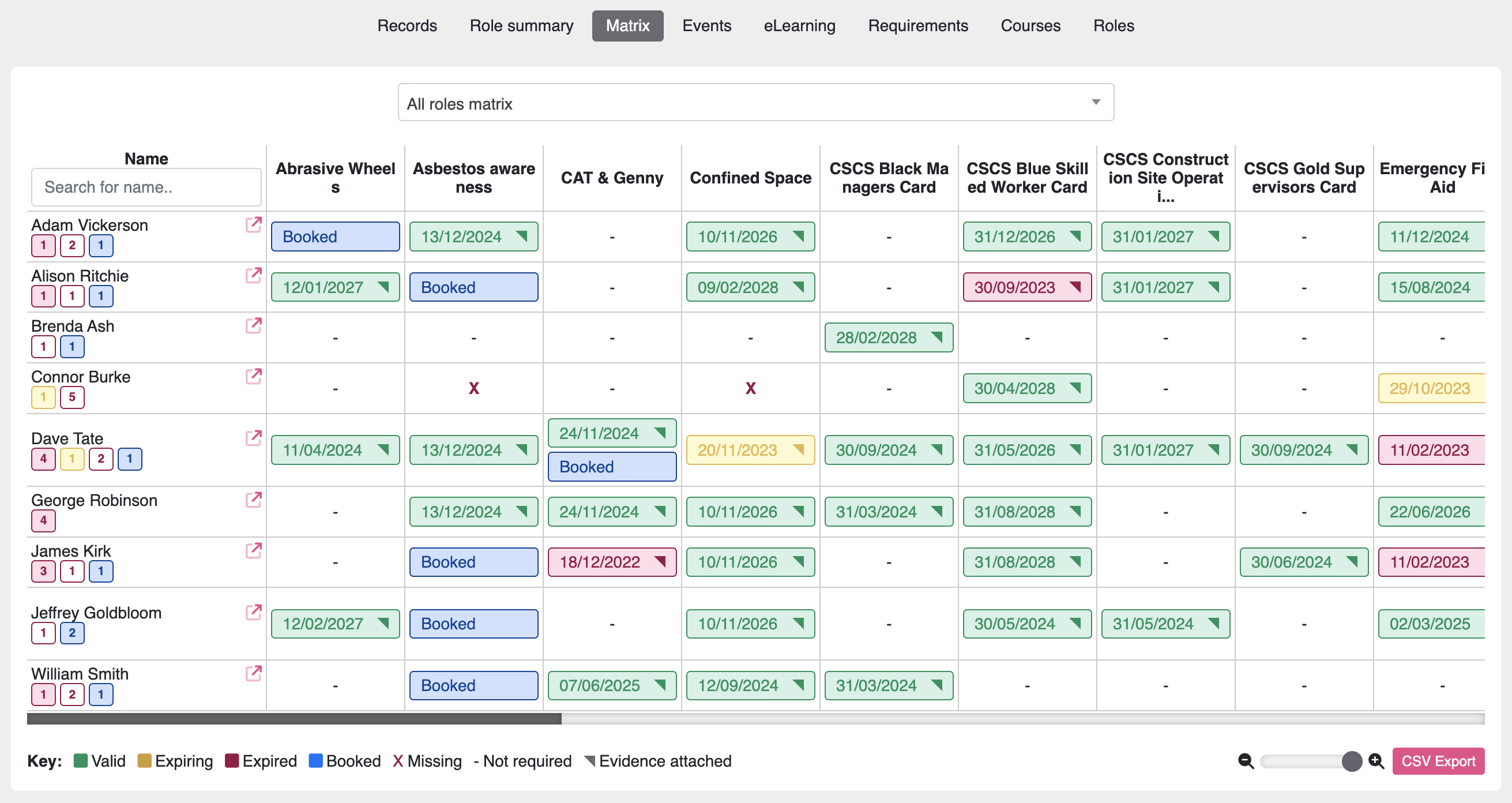

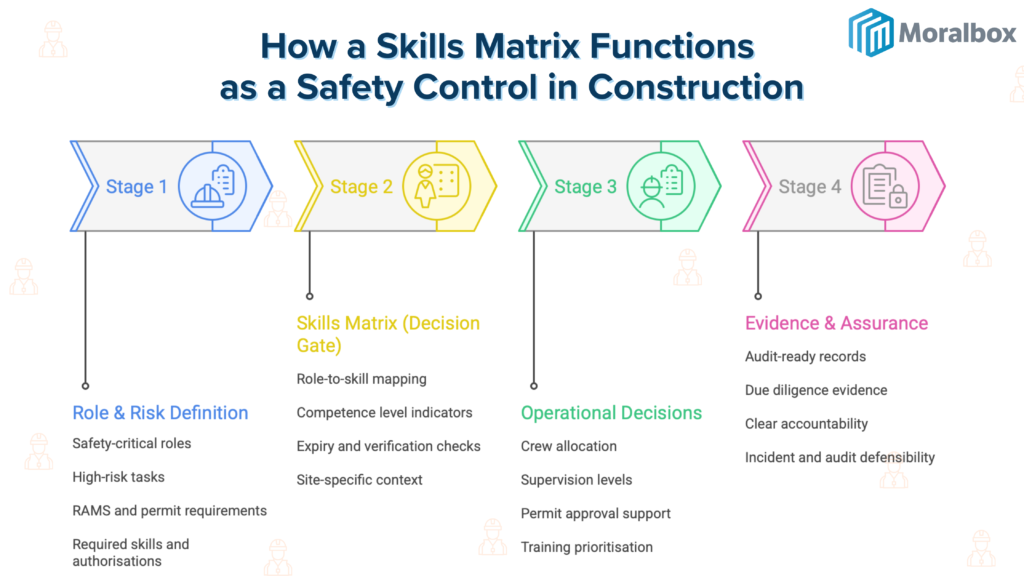

A skills matrix addresses this gap by shifting the focus from training attendance to demonstrable competence. It maps roles against required skills, certifications, authorisations and assessment status, creating a clear view of capability across the workforce.

In construction, this is critical for safety-critical roles such as plant operators, lifting supervisors, scaffold inspectors, temporary works coordinators and confined space operatives. A properly designed skills matrix allows organisations to:

- identify gaps in safety-critical capability before work starts,

- prioritise training based on risk rather than convenience,

- support crew allocation decisions with evidence,

- Demonstrate due diligence during audits and incident investigations.

Industry guidance increasingly highlights the need for structured approaches to competence development in multi-employer environments, where coordination, continuity and clarity of responsibility are critical (CITB, 2023).

To help organisations get started, a free construction skills matrix template is available for download to assess current capabilities and identify areas for immediate improvement.

Why spreadsheets break down at scale

Spreadsheets persist because they are familiar, not because they are effective. At a small scale, they may appear workable. As soon as organisations manage multiple sites, subcontractors or concurrent projects, spreadsheets introduce risk.

They depend on manual updates, provide no automated alerts for expiring competence, and cannot reliably show who was competent for which task on which site at a given moment. Version control is weak, audit trails are fragile, and data accuracy depends entirely on human discipline.

At scale, competence management becomes an operational control, not an administrative exercise. It requires live data, role-based logic and a defensible history.

A platform built for live competence control in construction

Once organisations recognise that competence must be managed dynamically, the requirement becomes clear: visibility, consistency and evidence.

Moralbox exists because construction environments demand more than static records. It is built to manage competence in the context of live projects, shifting roles and evolving risk. Rather than treating training as a standalone activity, it connects roles, skills, certifications and authorisations into a single operational view.

Moralbox supports construction teams by:

- mapping competence to roles and tasks rather than job titles,

- providing real-time visibility of workforce capability across sites,

- automatically tracking expiries for tickets, medicals and authorisations,

- maintaining consistent competence controls across subcontractors and temporary labour,

- preserving an auditable record of competence decisions over time.

This means construction site managers can allocate crews with confidence, compliance teams can respond to audits without last-minute data gathering, and leadership teams can see emerging skills gaps before they translate into incidents or delays with the help of a skills matrix and a centralised dashboard.

For organisations scaling operations, Moralbox turns competence management into a proactive control rather than a reactive burden.

👉 Suggested reading: How to Avoid Workplace Injury Cases Through Proactive Prevention. Shows how, in practice, organisations reduce injuries by shifting from reactive compliance to proactive risk control, while also strengthening competence, supervision and early intervention.

What effective competence management delivers in practice

When competence is visible, current and defensible, safety systems begin to function as intended. Controls such as RAMS, permits to work, and supervision stop operating in isolation and start aligning with the real capability of the workforce on site. This shifts safety management from assumption-based to evidence-led.

In practical terms, effective competence management delivers the following outcomes:

- RAMS that reflect reality on site

Task risk assessments align with the actual skills and authorisations of the people carrying out the work, reducing reliance on generic or outdated assumptions. - Stronger, risk-focused supervision

Supervisors spend less time chasing paperwork and more time managing live risk, because competence status is already verified and visible. - More confident crew allocation decisions

Operatives are assigned based on their verified capabilities rather than availability alone, thereby reducing exposure in safety-critical activities. - Audit readiness without disruption

Audits and client reviews become confirmation exercises rather than last-minute data scrambles, with evidence available for who was competent, when and where. - Reduced incidents linked to competence gaps

Near misses and incidents driven by expired tickets, unverified roles or informal task escalation become less likely. - Competence is treated as an operational control

Training and skills management move out of administration and into day-to-day project control, alongside programme, cost and quality.

Conclusion: making competence visible, current and defensible

Construction safety does not fail because organisations lack procedures or training. It fails when competence becomes invisible. As projects evolve, workforces change, and roles shift, static training records and spreadsheets cannot keep pace. What appears compliant on paper no longer reflects reality on site.

This guide has shown why competence must be managed as a live operational control. A skills matrix provides the structure to define what capability is required and where gaps exist, but at scale, it must be supported by systems that keep that information current, connected to site activity and defensible under scrutiny.

Platforms such as Moralbox are built for this purpose. By linking roles, skills, certifications and authorisations into a single, live view, Moralbox enables construction organisations to allocate crews based on verified competence, anticipate compliance risks and respond confidently to audits and inspections. The outcome is not just better record-keeping, but stronger control of risk where it matters most: on-site.

For an industry operating under constant pressure and scrutiny, making competence visible is no longer optional. It is foundational to safe, compliant and resilient construction operations.

FAQs

What is the difference between training and competence?

Training is participation in learning activities. Competence is the demonstrated ability to perform a task safely and effectively under real site conditions.

Why is construction particularly exposed to competence gaps?

High workforce turnover, subcontracting models, and constantly changing site conditions make manual, fragmented systems difficult to maintain accurately.

Do regulators require digital competence systems?

Regulators require evidence that competence is managed effectively. Digital systems increasingly provide the most reliable means of maintaining and demonstrating that evidence.

References

Abikenova, S.K., Oshakbayeva, Z.O., Bekmagambetov, A.B. and Sarybayeva, I.E. (2023). The role of professional competencies in developing a culture of safety in the workplace. European Journal of Sustainable Development, 12(4), pp. 237-246.Available at: https://doi.org/10.14207/ejsd.2023.v12n4p237.

2023 Industry Training Board (ITB) review: Transforming the construction workforce (2025). Available at: https://assets.publishing.service.gov.uk/media/679a1275a39e422368d10dd3/2023_Industry_Training_Board__ITB__review_Jan_2025.pdf.

Health and Safety Executive (HSE) (2024) Work-related fatal injuries in Great Britain 2023/24. Available at: https://www.hse.gov.uk/statistics/fatals.htm.

Occupational Safety and Health Administration (OSHA) (2023) Fall prevention campaign: Falls are the leading cause of death in construction. United States Department of Labor. Available at: https://www.osha.gov/stop-falls.

Rahman, F.A. (2022) ‘A safety competencies systematic literature review’, Sustainability, 14(11), p.6885. Available at: https://www.mdpi.com/2071-1050/14/11/6885

Ananya is a Marketing Executive at Moralbox, passionate about creating content that connects learning with business impact.