Introduction: Understanding How to Avoid Workplace Injury

Every morning, workers across the country start their day expecting to return home safe. Yet sometimes, ordinary routines turn into life-altering moments. Understanding how to avoid workplace injury is crucial, as most workplace tragedies don’t begin with reckless acts or freak accidents; they begin with small oversights like a skipped briefing, an expired certificate, or a task carried out without proper planning.

In this article, we explore how to prevent workplace injuries by examining three recent incidents that resulted in £960,000 in Fines and lives changed forever. Each case is real, the outcome was preventable, and all of them offer lessons for leaders responsible for safety and training.

We will look at:

- A fatal high-pressure jetting accident.

- A hand amputation during a boat lift.

- A crushing maintenance injury involving a loading shovel.

Together, these stories show how gaps in training and communication can lead to irreversible harm. After we review what happened, we will discuss how stronger systems of learning and verification could have prevented such workplace injury claims. Finally, we will explore how a modern compliance platform like Moralbox can help organisations build safer, more accountable workplaces.

TABLE OF CONTENTS

The Cases: Real Workplace Injuries That Could Have Been Prevented

Case 1: Fatal Jetting Operation

On 10 December 2022, a 51-year-old drainage engineer was preparing a high-pressure jetting system for use. It was a bitterly cold morning, with temperatures reported at around –3°C to –4°C. As he began priming the system, a loud explosion occurred. The hose end whipped upward and struck him in the head. He was placed into an induced coma and died on 27 December 2022 (Health and Safety Executive, 2025a).

Further investigation revealed that there was no documented safe system of work for the activity, and several jetting vehicles had defective hose-securing vices. The company also had no procedure for working in extreme cold and had not provided sufficient supervision or refresher training (Construction Enquirer, 2025).

The court fined the employer £800,000 plus costs, but no penalty could undo the human loss. Family and colleagues remembered the engineer, a devoted father of three, as hardworking and kind. His death serves as a painful reminder that safety systems must be more than written policies; they must be living processes that guide daily actions and show others how to avoid workplace injury.

Case 2: Hand Amputation During Boat Lift

Five months later, in May 2023, a worker assisting with a routine boat lift at a Norfolk marina suffered a devastating injury. While raising the boat with a telehandler, he trapped his hand beneath the forks. The crushing force amputated one of his fingers (Health and Safety Executive, 2025b).

Investigators later discovered that no lift plan existed, and staff had not received the required training to carry out or supervise the operation. There was also no proper communication or supervision during the lift. The entire incident was deemed “wholly avoidable” had a simple lift plan and trained operators been in place (HSM Search, 2025).

The company had to pay more than £2,000 in fines. Although the fine was relatively small, the impact on the injured worker was permanent.

Case 3: Life-Changing Crush During Maintenance

In another case, a maintenance worker at a waste-recycling site was repairing a hydraulic leak on a loading shovel when the bucket suddenly dropped on him. The impact fractured his ribs, leg, and foot and shattered his pelvis into three pieces (Health and Safety Executive, 2025c).

He was airlifted to the hospital and underwent several major operations. Once an active man who regularly exercised, he now struggles with basic mobility.

The investigation found that the company had not carried out a risk assessment for the task and had no safe system of work for isolating hydraulics. Additionally, the worker had not received adequate instruction, training, or supervision (Davies-Dennis, 2025). The organisation paid over £160,000 fines and a victim surcharge (Maddocks, 2025).

This case demonstrates that routine maintenance work can become dangerous when safety documentation and control measures are lacking, causing avoidable workplace injuries.

👉 For more insights into common risk factors and prevention strategies, you can also read our related guide: What Is the Biggest Cause of Workplace Injury and How SMEs Can Stay Ahead of Claims.

How These Tragedies Could Have Been Prevented: Learning from Workplace Injury Claims

When examined together, these incidents reveal a pattern of oversight that is sadly familiar across many industries. In each case, there were clear opportunities to prevent harm and demonstrate how to avoid workplace injury in practical ways.

Firstly, risk assessments and safe systems of work should have been written, reviewed and followed. Each job carried specific risks that required planning: pressure in cold conditions, suspended loads, and hydraulic isolation. Secondly, training and competence verification were missing or outdated. If management had clear visibility of training records, they could have confirmed whether workers were qualified to carry out their tasks safely and avoid accidents at work.

Furthermore, toolbox talks and pre-task briefings could have made a difference. A five-minute discussion before the job, focusing on the conditions, hazards, and control measures, might have been enough to prevent all three incidents. Lastly, supervision and record-keeping failed to ensure task execution under safe conditions, one of the leading causes of workplace injury claims.

Building Safer Systems with Moralbox

Preventing such incidents requires more than policies and posters. It demands a system that integrates training, verification and communication into everyday operations. This is exactly where Moralbox plays a vital role.

With Moralbox, organisations can:

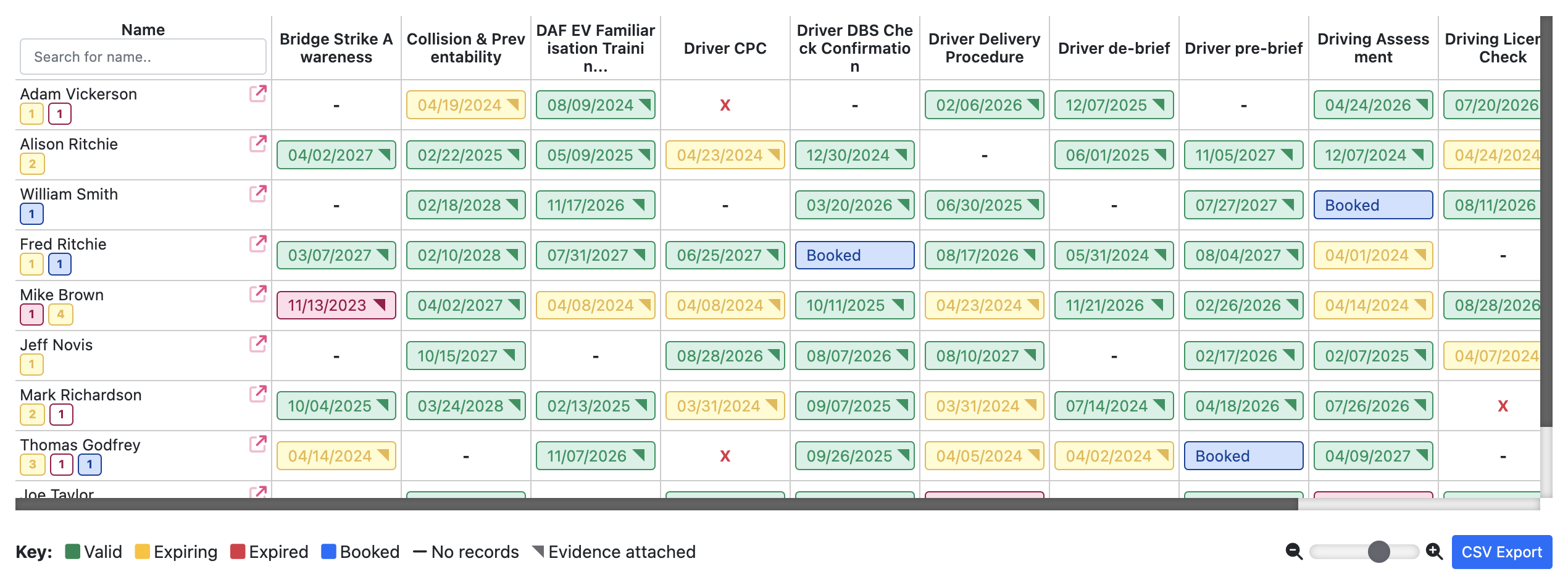

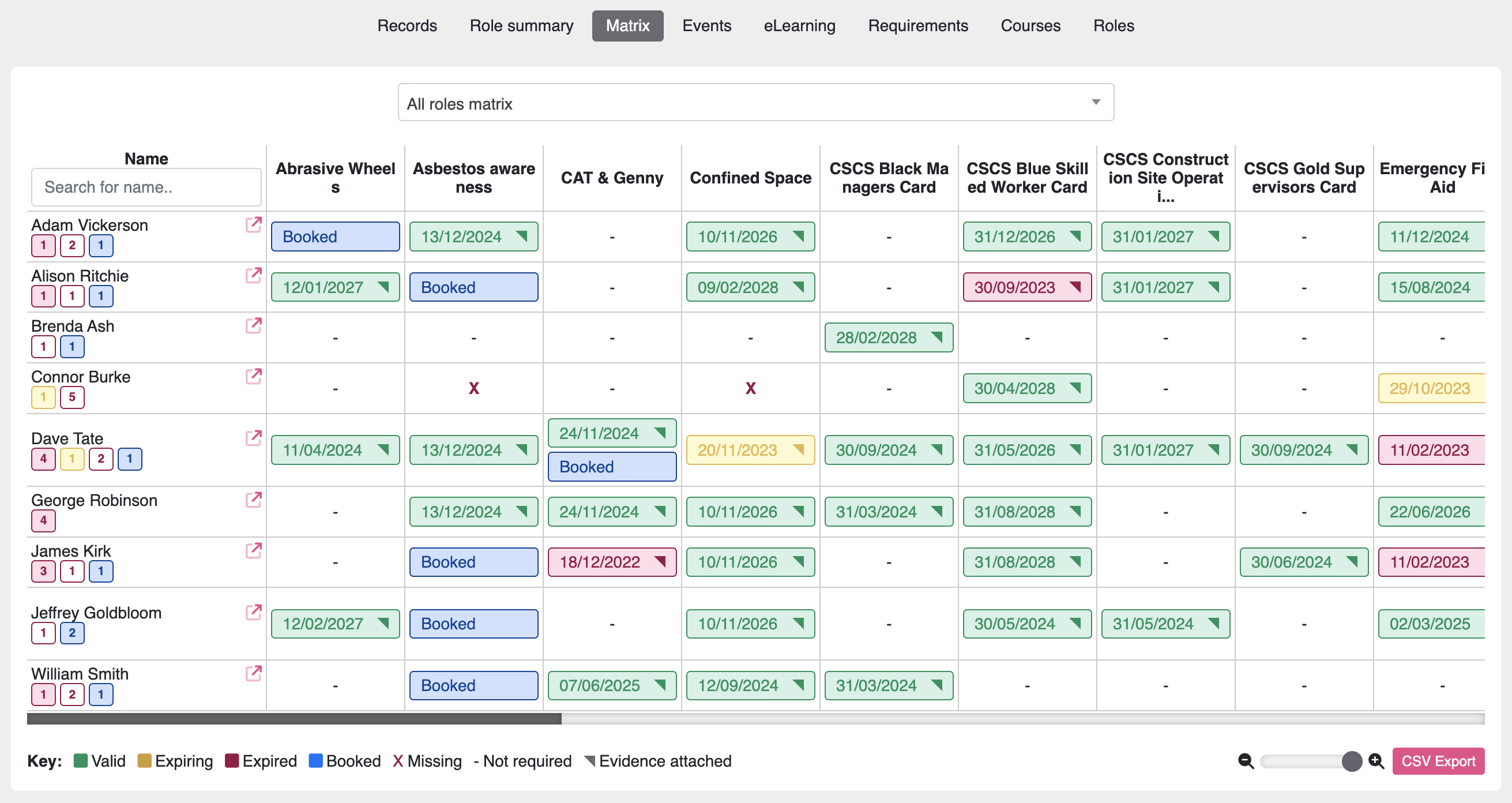

This offers a live overview of every employee’s qualifications and expiry dates. It highlights missing or outdated training before a task begins, ensuring high-risk work to competent staff only. If this system had been in place, supervisors could have identified expired certifications in both the jetting and maintenance cases before allowing the work to start.

With this, leaders can monitor staff development and compare current skills against what’s required for each role. This feature reveals hidden training gaps, supports professional growth, and ensures tasks are always matched with the right capabilities. It directly addresses the lack of verified competence seen in all three incidents.

3. Toolbox Talks and Safety Briefings

Through these, teams can conduct and record essential safety discussions before work begins. Attendance, topics, and key points are logged automatically. A short talk on freezing weather risks or hydraulic isolation could have reminded workers of procedures that might have saved lives.

The Email Reminders and Alerts feature automatically notifies managers and staff about upcoming training expirations, overdue toolbox talks, or unreviewed risk assessments. This prevents the oversight that so often precedes serious incidents. With automated notifications, compliance becomes continuous rather than crisis-driven.

Finally, these reports provide instant, audit-ready evidence of compliance. Managers can access complete records of training, toolbox talks, and competence data in seconds. This transparency builds confidence across the organisation and demonstrates accountability to inspectors, auditors, and employees alike.

Together, these features help organisations move from reactive compliance to proactive prevention. With Moralbox, safety becomes something you do every day and not something you check once a year.

If you would like to see how Moralbox can help your organisation strengthen compliance, streamline training, and prevent accidents before they occur, Book a Free 15-Minute Discovery Call with our experts today. Together, let’s make every workday a safe one.

Lessons Learned and Future Steps

From these incidents, several key lessons emerge about how to avoid workplace injury. Firstly, routine work is never risk-free. Every task deserves a moment of reflection to identify potential hazards. Secondly, training and verification must be ongoing, not one-time exercises. Skills fade, systems change, and new hazards emerge, which is why refresher training and active tracking are essential.

Thirdly, communication saves lives. Regular toolbox talks, even short ones, foster awareness and accountability. Fourthly, documentation matters. If it is not written down, tracked, and verified, it is difficult to prove or reinforce. Finally, prevention is always less costly than response, whether it’s financially, operationally, or emotionally.

The future of workplace safety lies in digital learning ecosystems that make training and accountability visible at all times. With systems like Moralbox, organisations can adapt quickly, monitor compliance, and ensure safety is sustained, not static.

Conclusion

Each of these three real-world and recent stories demonstrates how easily preventable oversights can lead to tragedy. Yet they also show that the solutions are within reach. Through structured training, verified competence, and transparent communication, workplaces can transform from reactive environments to proactive learning cultures.

By adopting modern safety and compliance platforms such as Moralbox, leaders can replace uncertainty with confidence and paperwork with prevention. Most importantly, they can protect the lives and well-being of the people who make their organisations run every day.

References

Construction Enquirer (2025) Exploding jet hose killed drainage engineer. Available at: https://www.constructionenquirer.com (Accessed: 4 November 2025).

Davies-Dennis, P. (2025) Waste company fined £160,000 after father of two suffers life-changing injuries, Circular Online. Available at: https://www.circularonline.co.uk/news/waste-company-fined-160000-after-father-of-two-suffers-life-changing-injuries/ (Accessed: 4 November 2025).

Health and Safety Executive (2025a) Lanes Group Limited fined £800,000 after investigation into death of devoted father. Available at: https://press.hse.gov.uk/2025/10/06/lanes-group-limited-fined-800k-after-investigation-into-death-of-devoted-father/ (Accessed: 3 November 2025).

Health and Safety Executive (2025b) Marina fined after worker injured during boat lift. Available at: https://press.hse.gov.uk/2025/10/06/marina-fined-after-worker-injured-during-boat-lift/ (Accessed: 3 November 2025).

Health and Safety Executive (2025c) Worcester waste company fined after worker suffers life-changing crush injuries. Available at: https://press.hse.gov.uk/2025/10/02/worcester-waste-company-fined-after-worker-suffers-life-changing-crush-injuries/ (Accessed: 3 November 2025).

HSM MAGAZINE – Marina fined after worker injured during boat lift (2025) Hsmsearch.com. Available at: https://www.hsmsearch.com/Marina-fined-worker-injured-boat-lift (Accessed: 4 November 2025).

Maddocks, A. (2025) England | £2.5m fine after worker crushed by skip wagon, EHS Compliance Experts | Barbour EHS. Available at: https://barbour-ehs.com/news/fine-after-worker-crushed-by-skip-wagon/ (Accessed: 4 November 2025).

Ananya is a Marketing Executive at Moralbox, passionate about creating content that connects learning with business impact.