Manual handling is a critical aspect of many workplaces, yet it poses significant risks if not properly managed. Conducting thorough risk assessments is essential to identify potential hazards and implement measures to mitigate them. This guide provides detailed examples of manual handling risk assessments, offering practical insights to ensure workplace safety and compliance with UK regulations.

Understanding Manual Handling Risk Assessments

Manual handling involves transporting or supporting loads by hand or bodily force, including lifting, putting down, pushing, pulling, carrying, or moving loads. The Manual Handling Operations Regulations 1992 (MHOR) in the UK require employers to:

- Avoid hazardous manual handling operations as far as reasonably practicable.

- Assess any hazardous manual handling operations that cannot be avoided.

- Reduce the risk of injury from those operations so far as reasonably practicable.

Conducting a manual handling risk assessment is essential to ensure the safety and well-being of employees who engage in manual handling tasks. Here are the steps to carry out a thorough manual handling risk assessment:

1. Identify the Tasks

Identify all manual handling tasks that employees perform. This involves observing the workplace and consulting with staff to understand their daily activities. Common tasks might include lifting, carrying, pushing, pulling, and moving loads.

2. Identify the Hazards

Determine the potential hazards associated with each task. Consider factors such as:

• Load: Weight, size, shape, and stability of the load.

• Task: The nature of the task, including the movements required and the frequency of the task.

• Environment: Conditions in the work environment such as space, lighting, flooring, and temperature.

• Individual: The physical capabilities of the employees performing the tasks, including their fitness level and any health issues.

• Equipment: Availability and condition of any mechanical aids or tools used in the task.

3. Assess the Risks

Evaluate the risks posed by the identified hazards. This involves considering the likelihood and severity of potential injuries. Use a risk matrix to rate the level of risk, ranging from low to high.

4. Implement Control Measures

Introduce control measures to reduce or eliminate the risks (does manual handling need to be carried out at all?). Control measures can include:

• Engineering Controls: Use mechanical aids such as trolleys, hoists, and conveyor belts.

• Administrative Controls: Implement safe work procedures, provide training, and rotate tasks to reduce repetitive strain.

• Personal Protective Equipment (PPE): Provide appropriate PPE if necessary.

5. Record the Findings

Document the risk assessment findings, including the hazards identified, the risks assessed, and the control measures implemented. This helps in maintaining a record for future reference and compliance with legal requirements.

6. Review and Update

Regularly review and update the risk assessment. This should be done periodically or whenever there are significant changes in the workplace, such as new equipment, processes, or personnel. Ensure that control measures remain effective and relevant.

Examples of Manual Handling Risk Assessments

Example 1: Office Environment

Task: Lifting and Moving Boxes of Paper

- Task: Employees lift and carry boxes of paper from storage to printers.

- Load: Each box weighs approximately 10 kg.

- Environment: The storage room is cramped, with limited space for movement.

- Individual: Varied fitness levels among staff.

- Equipment: No lifting aids available.

Risk Assessment Findings:

- Hazards: Risk of back strain and musculoskeletal injuries due to repetitive lifting in a confined space.

- Control Measures:

- Use trolleys to transport boxes.

- Train staff on proper lifting techniques.

- Reorganise storage to allow more space.

Example 2: Warehouse Operations

Task: Stacking Pallets

- Task: Workers stack heavy pallets onto shelving units.

- Load: Pallets weigh up to 25 kg each.

- Environment: Adequate lighting but narrow aisles.

- Individual: Workers are trained but vary in strength and height.

- Equipment: Pallet jacks and forklifts available.

Risk Assessment Findings:

- Hazards: Risk of dropping pallets and causing injury due to the weight and awkward lifting positions.

- Control Measures:

- Implement mechanical lifting aids like forklifts.

- Conduct regular training sessions on safe stacking techniques.

- Ensure aisles are clear of obstructions.

Example 3: Construction Site

Task: Carrying Construction Materials

- Task: Workers carry bricks and other construction materials across the site.

- Load: Individual bricks weigh around 3 kg, but loads are often carried in batches.

- Environment: Uneven ground, varying weather conditions.

- Individual: Workers with varying levels of physical fitness.

- Equipment: Wheelbarrows and lifting straps available.

Risk Assessment Findings:

- Hazards: High risk of slips, trips, and falls, as well as musculoskeletal injuries from carrying heavy loads.

- Control Measures:

- Use wheelbarrows to transport materials.

- Ensure pathways are level and clear.

- Provide training on safe lifting and carrying techniques.

Resources for More Information

1. Health and Safety Executive (HSE): HSE Manual Handling

2. RoSPA (Royal Society for the Prevention of Accidents): RoSPA Manual Handling Training

3. IOSH (Institution of Occupational Safety and Health): IOSH Manual Handling

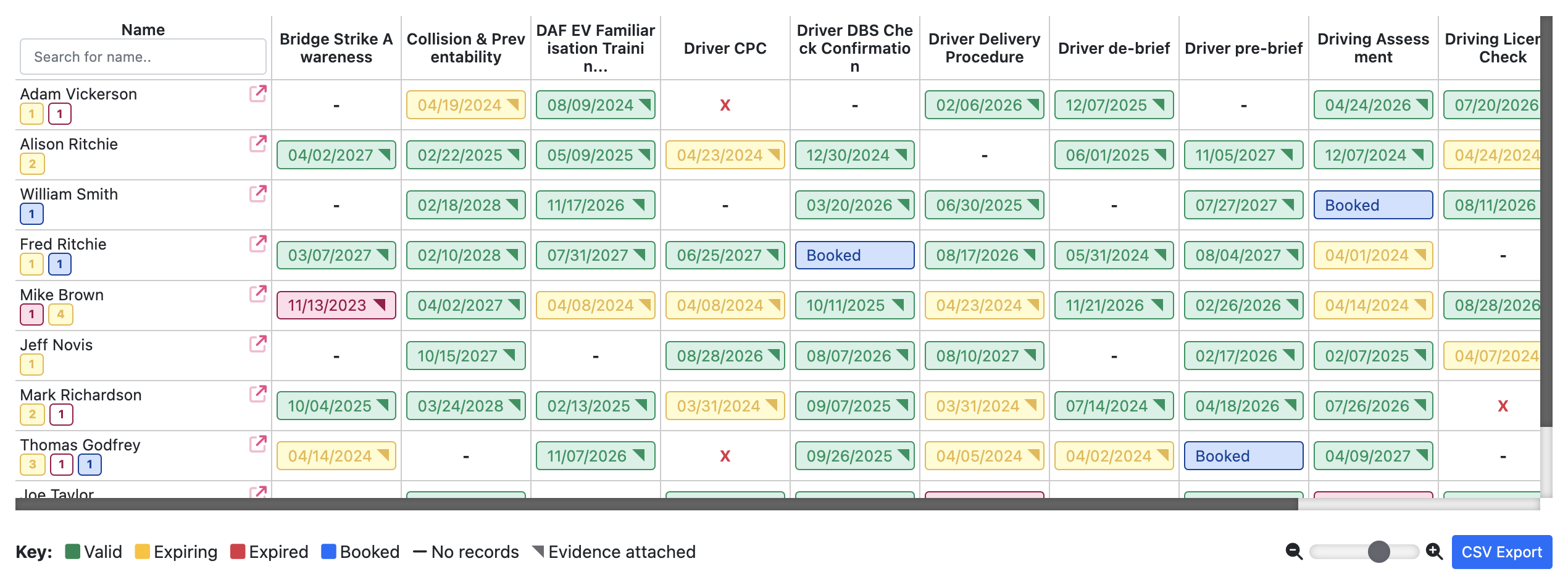

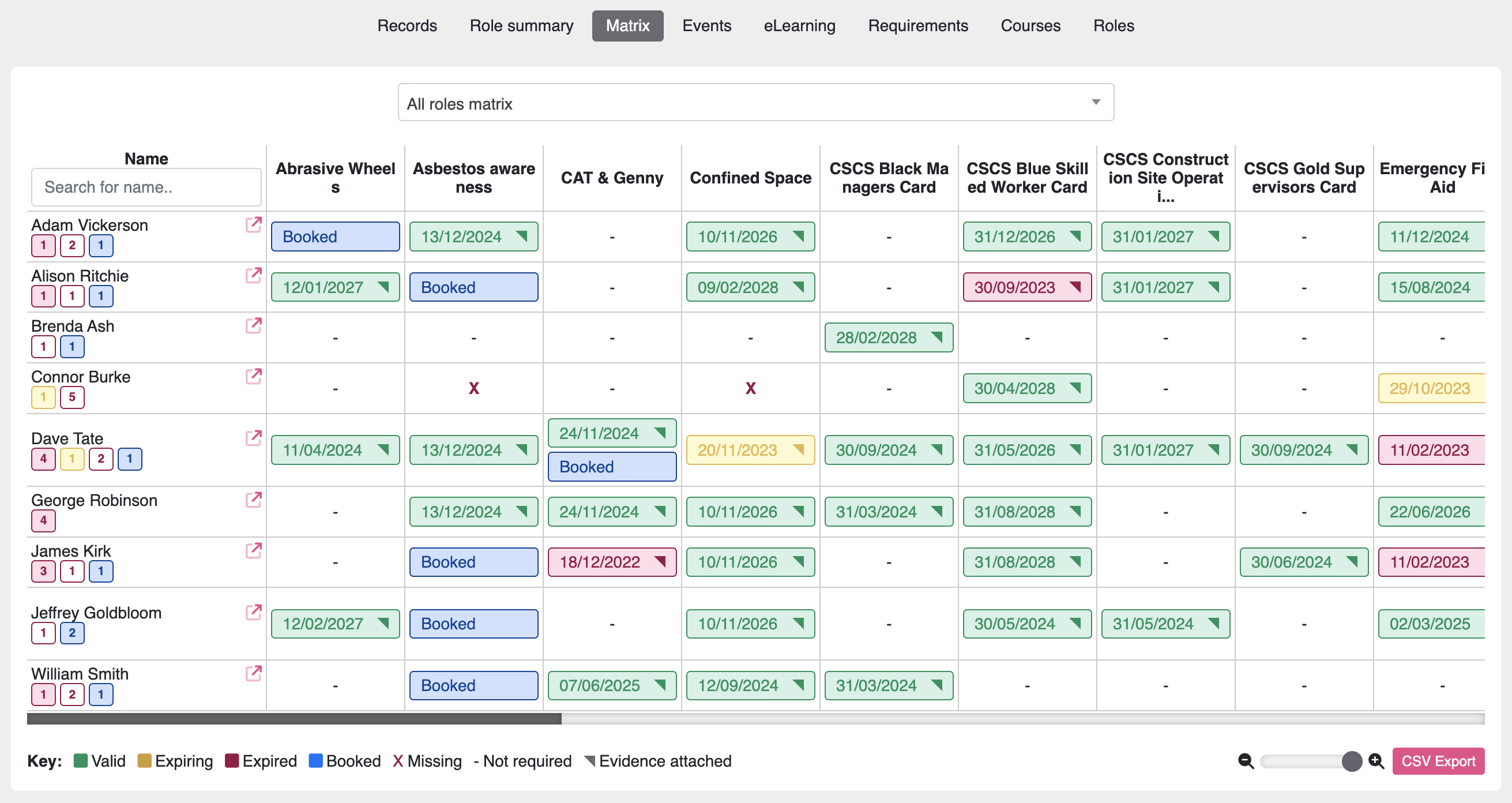

4. Use a training matrix to monitor Manual handling trainng

John is our co-founder and is responsible for software design and development and loves helping people solve problems using innovative software.