As a former Health and Safety Consultant with extensive experience in conducting inspections across construction sites and manufacturing facilities, I’ve seen the profound impact that a well-executed toolbox talk can have on workplace safety. These short, focused discussions are not just a formality but a critical component of a comprehensive safety strategy, aimed at preventing accidents and fostering a culture of safety awareness.

What is a Toolbox Talk?

Toolbox talks are a vital safety measure, providing a platform for discussing specific hazards and safety practices relevant to the day’s tasks. They offer a unique opportunity for open dialogue between supervisors and workers, ensuring that safety remains at the forefront of everyone’s mind. In industries where the work environment and hazards can change daily, such as construction and manufacturing, these talks are indispensable.

Real-World Impact

- Worldwide statistics emphasize the critical need for toolbox talks in maintaining workplace safety. In the USA, 2019 witnessed 711 deaths from falls in various industries, with 401 in construction, and about 658 annual deaths due to extreme heat, underscoring the importance of discussions on topics like heat exhaustion prevention. The same year saw 5,190 fatal injuries and over 2.8 million nonfatal injuries and illnesses, highlighting the necessity for ongoing safety education. 1

- In the UK, the Health and Safety Executive (HSE) noted 45 fatal injuries in the construction sector for 2022/23, illustrating the high risks associated with construction work. This data underlines the importance of toolbox talks in addressing specific hazards, such as falls from heights, which caused 40 fatal injuries, showcasing their vital role in enhancing worker safety. 2

- In Australia, the construction industry witnessed a decrease in fatalities by 2.6% from 2020 to 2021, with the industry recording 24 fatalities in a year. The serious injury claim rate remained high at 16.9 claims per 1,000 workers, indicating a need for ongoing safety initiatives. 3

- In South Africa, the Federated Employers Mutual Assurance Company (FEM) reported 6,077 accidents in the construction industry for 2022, with “struck by” incidents being the leading cause at 32.4%. The year also saw 47 fatalities, with motor vehicle accidents being a significant contributor. The average cost per accident was noted as R72,883, highlighting the financial impact alongside the human toll 4. Over a seven-year period leading up to 2022, FEM data showed 52,899 injuries requiring medical attention, with “struck by” incidents constituting 32.5% of these accidents5 .

Examples of Effective Toolbox Talks

1. Workplace Safety Practices

- Electrical Safety: Discussions on electrical hazards and preventive measures.

- Fire Safety and Prevention: Common causes of fires, use of fire extinguishers, and evacuation procedures.

- Lockout/Tagout Procedures: Controlling hazardous energy to prevent unexpected equipment start-ups.

- Distracted Working: Dangers of distractions, such as mobile phone use, especially when operating machinery.

2. Personal Protective Equipment (PPE)

- PPE Usage: Educating workers on the correct use of PPE to reduce exposure to hazards.

- Noise Exposure and Hearing Protection: Importance of using hearing protection in high-noise areas.

3. Fall Protection and Working at Heights

- Working at Heights: Fall protection and safety measures to reduce fatalities from falls.

- Ladder Safety: Proper selection, inspection, and use of ladders, including maintaining three points of contact.

4. Tool and Equipment Safety

- Hand and Power Tool Safety: Inspecting, using, and maintaining tools properly.

- Vehicle and Equipment Safety: Safe operation of vehicles and heavy equipment, including pre-use inspections.

5. Health and Environmental Hazards

- Hazardous Material Handling: Safe storage, use, and disposal of hazardous substances.

- Chemical Safety: Proper handling, storage, and disposal of chemicals, including understanding labels.

- Heat Stress Prevention: Hydration, recognizing signs of heat exhaustion or heat stroke.

- Cold Weather Operations: Risks associated with working in cold conditions, such as frostbite and hypothermia.

6. Ergonomics and Physical Health

- Ergonomics and Manual Handling: Proper lifting techniques and the use of mechanical aids to prevent injuries.

- Slips, Trips, and Falls: Preventing accidents by keeping walkways clear and surfaces clean.

7. Specialized Work Environments

- Confined Space Entry: Dangers of working in confined spaces, necessary permits, and procedures.

- Emergency Preparedness and Response: Site-specific emergency action plans, including evacuation routes and assembly points.

These topics can be customized based on the specific hazards and operations of a worksite, ensuring that the talks are relevant and engaging for the workers.

Leveraging Technology for Toolbox Talks

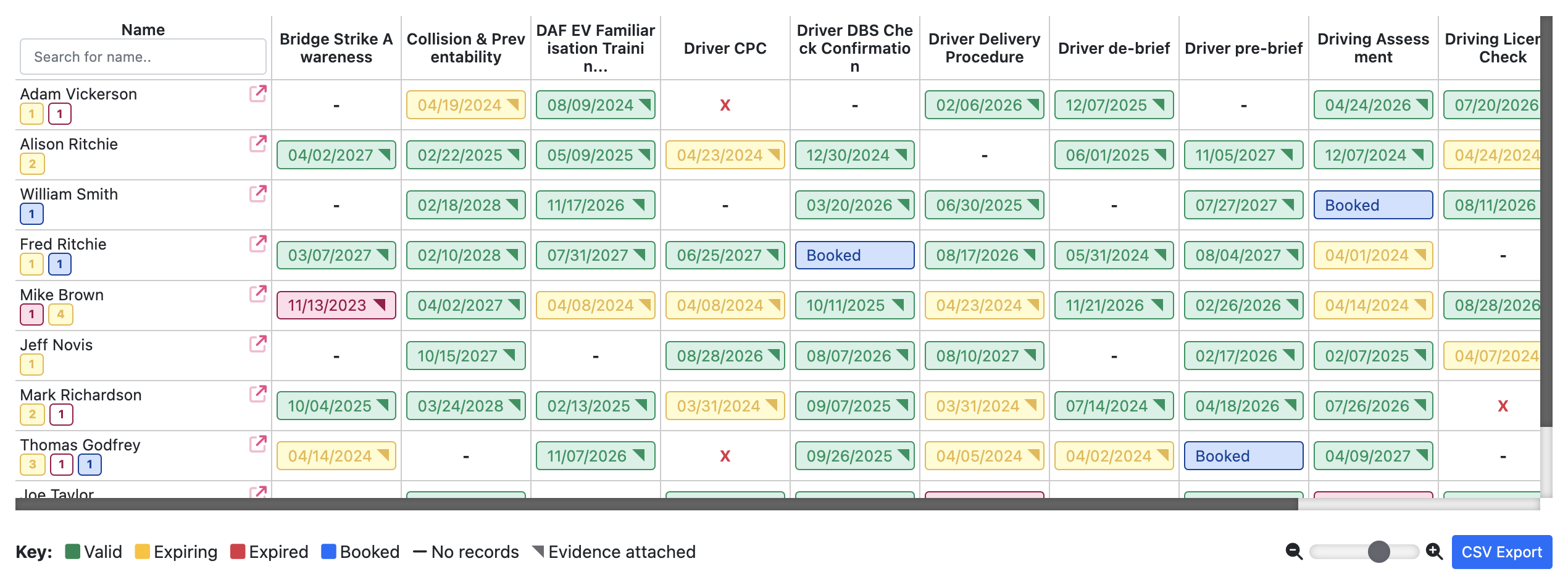

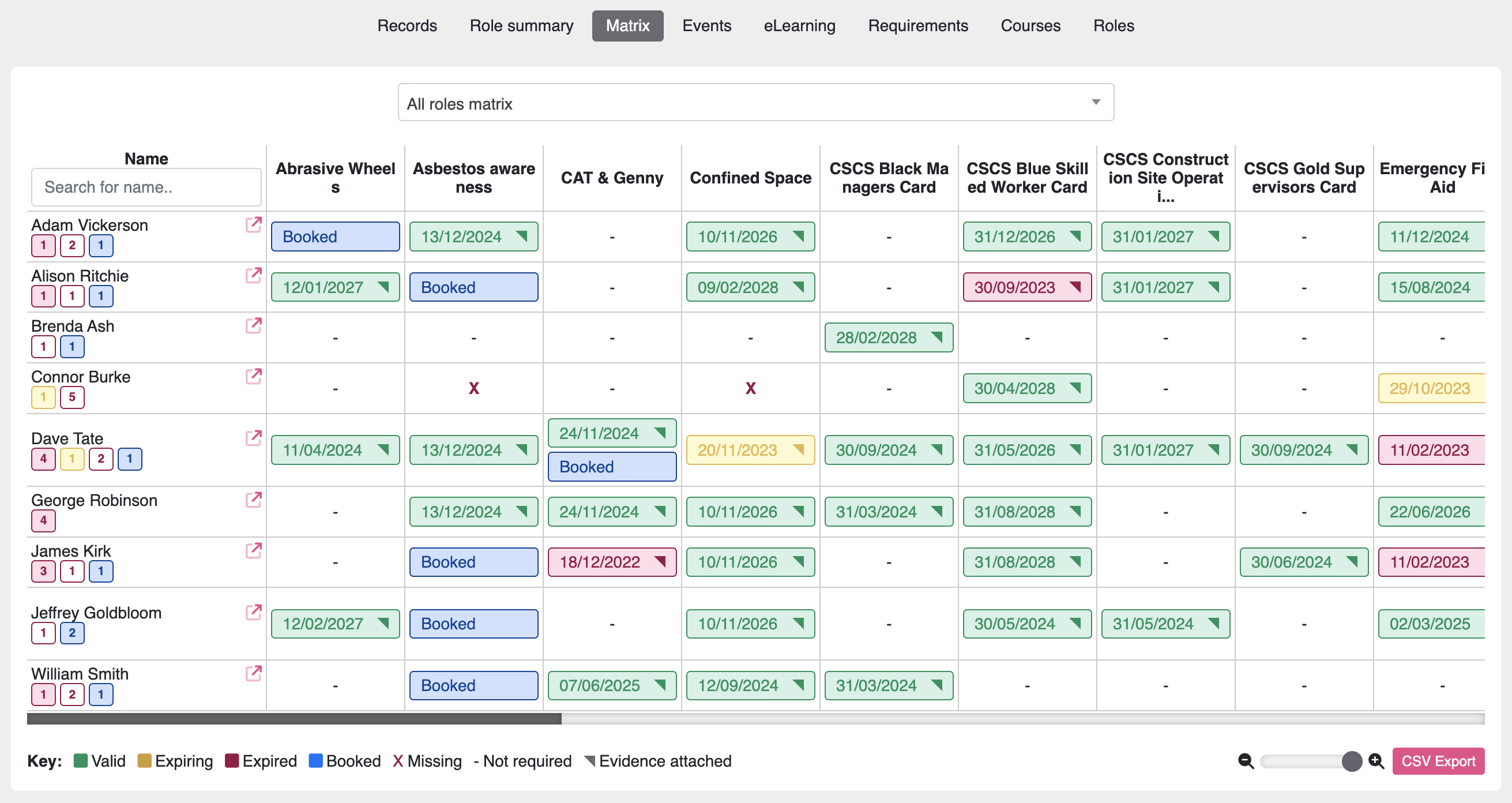

In today’s digital age, software solutions like Moralbox offer a streamlined way to deliver, log and manage toolbox talks, enhancing the efficiency and effectiveness of safety programs. These platforms allow for the scheduling of live sessions, digital logging of attendance, and ensuring that every necessary participant receives the information. A matrix ensures nobody misses a toolbox box they are required attend. This digital approach not only simplifies the management of toolbox talks but also provides a tangible record of ongoing safety efforts, contributing to a culture of accountability and continuous improvement.

Relevant Resources for Toolbox Talks

For those looking to deepen their understanding of what a toolbox talk is and integrate these practices more effectively, here are some useful websites:

- National Safety Council’s Workplace Safety Insights

- OSHA’s Safety and Health Topics

- CDC’s Workplace Safety and Health Topics

- HSE – Construction

- WISHNI – Guidance Documents

These resources offer valuable information on safety topics, guidelines, and best practices that can enrich your toolbox talk and safety programs.

Conclusion

Toolbox talks are a key pillar of workplace safety, offering a simple yet effective means to address the dynamic nature of hazards in industries like construction and manufacturing. By leveraging technology and drawing on real-world statistics to inform topics, we can significantly enhance the impact of these talks. As safety professionals, it’s our responsibility to continuously evolve our approaches to safety training, ensuring that every worker returns home safely at the end of the day.

References

- https://1streporting.com/blog/toolbox-talk-topics/ ↩︎

- https://www.hse.gov.uk/statistics/fatals.htm ↩︎

- https://www.worksafe.qld.gov.au/news-and-events/newsletters/esafe-newsletters/esafe-editions/esafe-construction/march-2023/construction-industry-stats-the-good-and-the-bad-news ↩︎

- https://www.fem.co.za/fem-2022-construction-industry-workplace-accident-statistics/ ↩︎

- https://www.bizcommunity.com/Article/196/494/227275.html ↩︎

Gordon is co-founder and CEO of Moralbox. He created the company vision and strategy. Gordon has over 10 years experience in occupational health and safety.